Search term must have more than 2 characters.

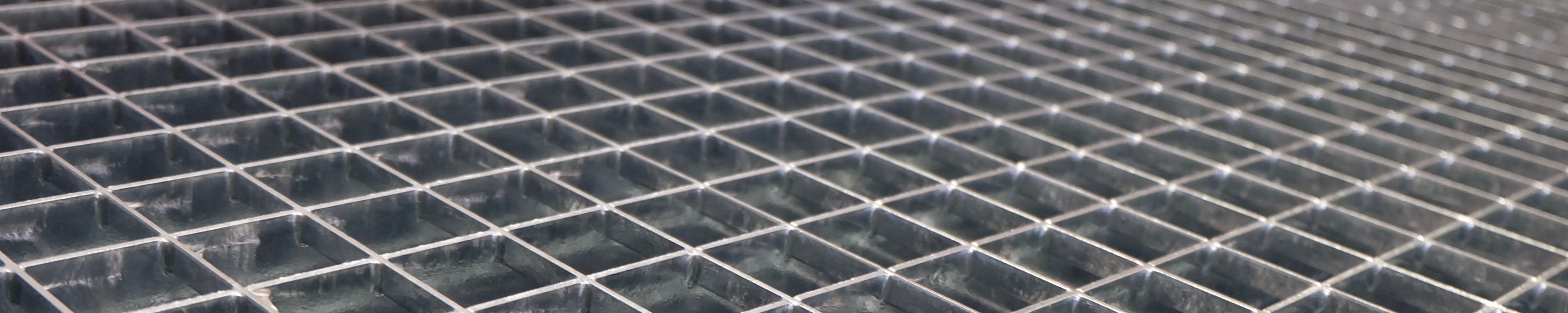

Pressed gratings “P”

High pressure

Filler bars are pressed into the supporting bars with pre-prepared grooves under high pressure. By using a high pressure force and a special shape of grooves in the support strip, the grates provide a rigid, torsion-resistant structure. Thanks to this, the load is evenly distributed. This method of manufacture allows for additional machining (cutouts, etc ...) without significant loss of bearing properties of the material.

PRESSURE

20 000 kN

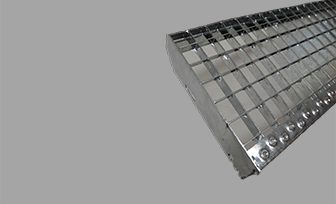

Welded gratings “SP”

Strong current

Filling rods are welded to the solid supporting bars with a pressure up to 1000 kN. At each point of the wires of the wire with the supporting bars a weld is formed. This guarantees exceptional strength and ability to evenly distribute the load. The grates are lined transversely by a method in which the double crimped rim along its entire length is always welded at each point with each carrier strip at two points.

ELECTRICITY

2 500 kVA